Get Quote

News

- Electrofusion Welding Machine or Butt Fusion Welding Machine which one?The polyethylene (PE) is the most common produced plastic, and although it is very used in sheets, polyethylene gabs, bottles or containers, we are going to focus on its use in pipes. The two most common methods to weld it are the electrofusion and the butt welding. Due to the characteristics, the polyethylene is ideal for the drinking water distribution networks, although it can have other uses in industrial applications, to protect cables and as part of the heating systems. Among the advantages that it has we can find its great flexibility, its lack of toxicity, its low maintenance costs, ease of installation and handling, its low roughness or its resistance to external agents and the corrosion. Coils of Plastic Tubing Although these are the two most common techniques, both the electrofusion like the butt welding, are relatively simple, it is essential to prepare the surfaces on which we are going to do the join and to know in great detail the procedure to do a good welding. At the moment of choosing what type of welding to use, we should take into account the type of work we are going to use, as regarding the reliability, both are similar systems. A factor that can result determinant at the moment of taking the decision is the flexibility of the PE pipes. With the butt welding it is better solve than with the electrofusion. The main advantages of each of the procedures are the following: Electrofusion welding It makes much easier the access when we have to weld in difficult situations or when we have little space to access the pipe. We can join polyethylene materials of different generations and thicknesses without weaken the welding. The cost of the installation is low, so it is very suitable to do it in private dwellings. The welding equipment is, compared to the butt welding, cheaper and lighter, what allows moving it with ease. It offers a wide range of solutions with simple power point and tapping saddle Butt welding machine It is possible to weld pipes with different generations of polyethylene. It is simple to eliminate the rusted layer, an essential step to do the join with guarantees. Through the removal of the melted material it is produced a self-cleaning of the welding. It doesn`t need additional fittings for joining, what simplifies the procedure. In pipes with a diameter higher to 200 millimetres is more efficient and economical. The pipe can be bended with ease without increasing imperatively the tension of the whole installation. The axial alignment and the round of the pipes are simple.

2018 06/06

- geomembrane membrane linerA geomembrane is very low permeability synthetic membrane liner or barrier used with any geotechnical engineering related material so as to control fluid (or gas) migration in a human-made project, structure, or system. Geomembranes are made from relatively thin continuous polymeric sheets, but they can also be made from the impregnation of geotextiles with asphalt, elastomer or polymer sprays, or as multilayered bitumen geocomposites. Continuous polymer sheet geomembranes are, by far, the most common. The manufacturing of geomembranes begins with the production of the raw materials, which include the polymer resin, and various additives such as antioxidants, plasticizers, fillers, carbon black, and lubricants (as a processing aid). These raw materials (i.e., the "formulation") are then processed into sheets of various widths and thickness by extrusion, calendering, and/or spread coating. Three methods used to manufacture geomembranes. Geomembranes dominate the sales of geosynthetic products, at 1.8 billion USD per year worldwide, which is 35% of the market. The US market is currently divided between HDPE, LLDPE, fPP, PVC, CSPE-R, EPDM-R and others (such as EIA-R), and can be summarized as follows:(Note that M m2 refers to millions of square meters.) Properties The majority of generic geomembrane test methods that are referenced worldwide are by the ASTM International|American Society of Testing and Materials (ASTM) due to their long history in this activity. More recent are test method developed by the International Organization for Standardization (ISO). Lastly, the Geosynthetic Research Institute (GRI) has developed test methods that are only for test methods not addressed by ASTM or ISO. Of course, individual countries and manufacturers often have specific (and sometimes) proprietary test methods. Physical properties The main physical properties of geomembranes in the as-manufactured state are: Thickness (smooth sheet, textured, asperity height) Density Melt flow index Mass per unit area (weight) Vapor transmission (water and solvent). Mechanical properties Applications Geomembrane installation as part of the construction of a base liner system of a landfill. Geomembranes have been used in the following environmental, geotechnical, hydraulic, transportation, and private development applications: As liners for potable water As liners for reserve water (e.g., safe shutdown of nuclear facilities) As liners for waste liquids (e.g., sewage sludge) Liners for radioactive or hazardous waste liquid As liners for secondary containment of underground storage tanks As liners for solar ponds As liners for brine solutions As liners for the agriculture industry As liners for the aquiculture industry, such as fish/shrimp pond As liners for golf course water holes and sand bunkers As liners for all types of decorative and architectural ponds As liners for water conveyance canals As liners for various waste conveyance canals As liners for primary, secondary, and/or tertiary solid-waste landfills and waste piles As liners for heap leach pads As covers (caps) for solid-waste landfills As covers for aerobic and anaerobic manure digesters in the agriculture industry As covers for power plant coal ash As liners for vertical walls: single or double with leak detection As cutoffs within zoned earth dams for seepage control As linings for emergency spillways As waterproofing liners within tunnels and pipelines As waterproof facing of earth and rockfill dams As waterproof facing for roller compacted concrete dams As waterproof facing for masonry and concrete dams Within cofferdams for seepage control As floating reservoirs for seepage control As floating reservoir covers for preventing pollution To contain and transport liquids in trucks To contain and transport potable water and other liquids in the ocean As a barrier to odors from landfills As a barrier to vapors (radon, hydrocarbons, etc.) beneath buildings To control expansive soils To control frost-susceptible soils To shield sinkhole-susceptible areas from flowing water To prevent infiltration of water in sensitive areas To form barrier tubes as dams To face structural supports as temporary cofferdams To conduct water flow into preferred paths Beneath highways to prevent pollution from deicing salts Beneath and adjacent to highways to capture hazardous liquid spills As containment structures for temporary surcharges To aid in establishing uniformity of subsurface compressibility and subsidence Beneath asphalt overlays as a waterproofing layer To contain seepage losses in existing above-ground tanks As flexible forms where loss of material cannot be allowed.

2018 06/06

- Invitation to Visit CHINAPLAS 2018- Butt Fusion Welding Machine,Extrusion Welder,Hot Wedge WelderInvitation to Visit CHINAPLAS 2018---- Booth No.6.1R33 We cordially invite you and your colleagues to visit our booth at CHINAPLAS 2018, which will be held on 24-27 April 2018 at National Exhibition & Convention Center (NECC) in Hongqiao, Shanghai, PR China. Being our honored guests, entrance fee to CHINAPLAS 2018 at RMB80 (for 4-day show visit) will be waived for you and your colleagues.

2018 04/13

- ASIAWATER 2018 From 10-12 Aprli At KLCCMM-Tech sincerely invite you and your staff to visit our stand at KLLC from 10-12 April 2018,held in KUALA LUMPUR, MALAYSIA. BOOTH NO.HALL 1&2, G110 We look forward to meeting you here.

2018 04/01

- MM-Tech Will Attend to ASIAWATER 2018 From 10-12 Aprli At KLCCHebei MingMai Technology Co.,LTD sincerely invite you and your staff to visit our stand at KLLC from 10-12 April 2018,held in KUALA LUMPUR, MALAYSIA. BOOTH NO.HALL 1&2, G110 We look forward to meeting you here.

2018 01/23

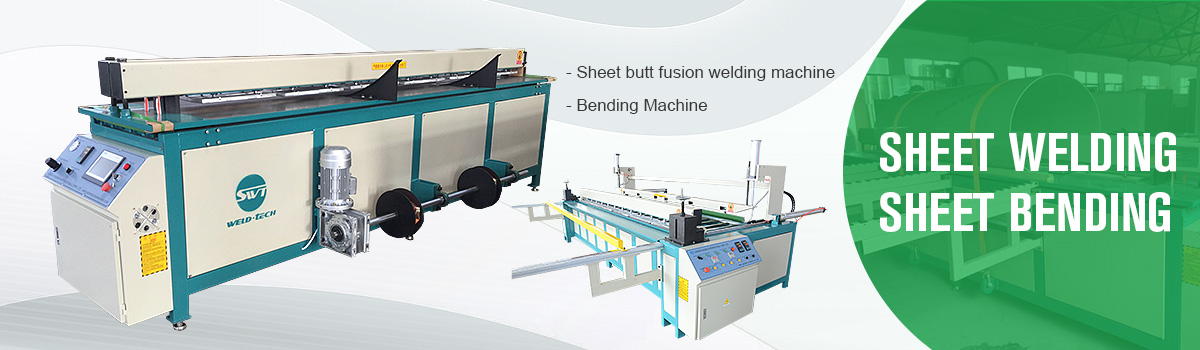

- MM-Tech Thermoplastic Welding TechnologyHebei MingMai Technology Co.,LTD is the world's most unique manufacturer of thermoplastic welding technology (butt welding machines, bending and edging machines, hand held extrusion welders, hot air welding equipment, testing equipment,Sheet Bending Equipment.

2017 11/20

- 2018 Interplastica will take place from 23 to 26 January 2018 in MoscowHebei MingMai Technology Co.,LTD will be attend to 2018 Interplastica , which will take place from 23 to 26 January 2018 in Moscow.

2017 11/08

- Butt Fusion Machine & Electrofusion Machine MethodsHdpe Pipe Joining Methods Polyethylene pipes or HDPE Electrofusion fittings - HDPE Spigot Fittings are connected with each other by melting or mechanical fittings. External to the tubes made of other materials than polyethylene squeeze fittings, flanges or other purpose-built can be combined with transition adapter. Connection fittings according to the convenience is the place to be used. Two methods are used for fusion welding by means of: Electrofusion (EF) Welding Butt Fusion Welding Electro Fusion Welding Electrofusion welding process principle, Electrofusion Welding Machine and to be joined together of the parts which socket is in the copper wire to give electricity by heating both parts from the outside of a certain portion by melting together the fusion is to make. Electrofusion welding method 20 mm to 1200 mm diameter pipe can be welded. Electrofusion welding method is carried out in accordance with DVS 2207. Butt Fusion Welding Butt welding method for welding of polyethylene pipes and fittings is currently the most widely used welding method. Coupling butt welding method, a butt welding the ends of the tube to be welded using heating plate both ends with a certain pressure under heat by pushing toward each other is the process of fusion welding. Butt welding method of joining pipes with diameters up to 1200 mm can be welded. Butt weld bonding method is carried out in accordance with DVS 2207. BUTT FUSION WELDING and ELECTRO FUSION WELDING METHODS COMPARISON OF WELDING Both sources by licensed welders and DVS 2207 is made in accordance with the method of butt welding and electrofusion welding is not no quality difference. From the labor resources in the right place in order to get the best results, you need to be sure that the correct method is used. The location of the source in terms of seeing butt welding method of welding, electro fusion welding method is advantageous compared to. The floor will fit in high places or places of welding machines welding electrofusion welding is more advantageous where necessary. Ease of welding processes according to their degree of butt welding is more advantageous. Electrofusion welding method be the factors that determine the quality of the source is greater than supply (pipe ovality, electrical voltage and continuity, dimensional tolerances, etc.). therefore, a butt weld, electrofusion welding is an advantageous. Resource costs according to the terms of the electrofusion welding butt welding is more advantageous. After welding electrofusion welding is more advantageous in terms of image.

2017 11/07

- Hdpe Pipe Welding Machine Joining MethodsHdpe Pipe Joining Methods Polyethylene pipes or HDPE Electrofusion fittings - HDPE Spigot Fittings are connected with each other by melting or mechanical fittings.

2017 11/07

Email to this supplier